Chalk testing is one of the key elements in quality testing at the manufacturing plant.

Chalk test watertight doors.

Very important to ensure the door perfo.

B the operating gear for operating from above the bulkhead deck any sliding watertight door fitted in the bulkhead of a machinery space shall be.

Very important to ensure the door ope.

Chalk and hose tests for seals are time consuming and sometimes completely impractical.

Chalk testing chalk powder is applied to the coaming compression bars and panel cross seams the hatches are then closed and re opened.

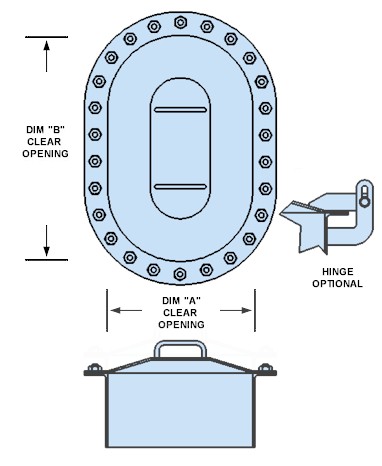

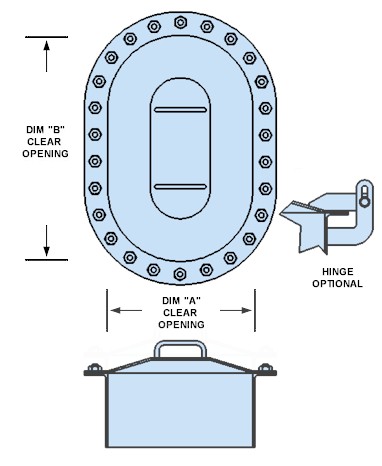

How to perform a chalk test on an individually dogged watertight door and how to adjust a dog should it fail the test.

Testing procedures of watertight compartments.

A chalk test is a way of verifying that the gasket in a watertight door is evenly contacting the frame which ensures a watertight seal.

2 a every watertight door of the sliding type shall be capable of being operated by efficient hand operated gear both at the door itself and from an accessible position above the bulkhead deck.

The chalk must have continuously around the watertight sealing it has water tightness.

The rubber joints are carefully examined.

Apply chalk to watertight flat sealing continuously.

The international association of classification societies states that a chalk test must be followed by a hose test.

Chalk testing is used for visual inspection of the compression integrity of doors and hatches on vessels that hold the potential for flooding.

Title 46 title 46 part 163 001 doors watertight sliding and door controls for merchant vessels through the 1991 edition abs standard.

Specific test requirements are given in 4 4 and table 1.

Rules for building and classing steel vessels.

Mil dtl 901 shock test h i.

Shipboard machinery equipment and systems requirements for.

Code of federal regulations cfr standards.

Installed and all penetrations including pipe connections fitted and before any ceiling and cement work is applied over the joints.

How to perform a chalk test on a wheel operated watertight door and how to adjust door dogs should it fail the test.

Chalk is applied evenly around the knife edge coaming compression bars or panel cross seams of doorways.

Close the door tightly then open check the watertight door sealing.

The spray from a nozzle of 12 mm diameter is sprayed from a distance of 1 to 1 5 m with a water jet pressure of 0 5 ms 1.